Float glass and Clear glass

Float glass is the ordinary glass. The float glass production is done using the common glass making raw materials, typically sand and soda ash. “Float glass” is named after its manufacturing process in which the molten glass floats when introduced into a bath of molten tin.

The float glass has a greenish tint due to the iron content in the raw materials. The float glass is the component of many other composite glass types like laminated glass, low E glass, etc.

The clear glass is similar to float glass but the iron content is reduced to diminish the greenish tint. This is made possible by controlling the iron oxide content. Unlike float glass, clear glass is more transparent and has considerably low greenish tint.

Low iron glass

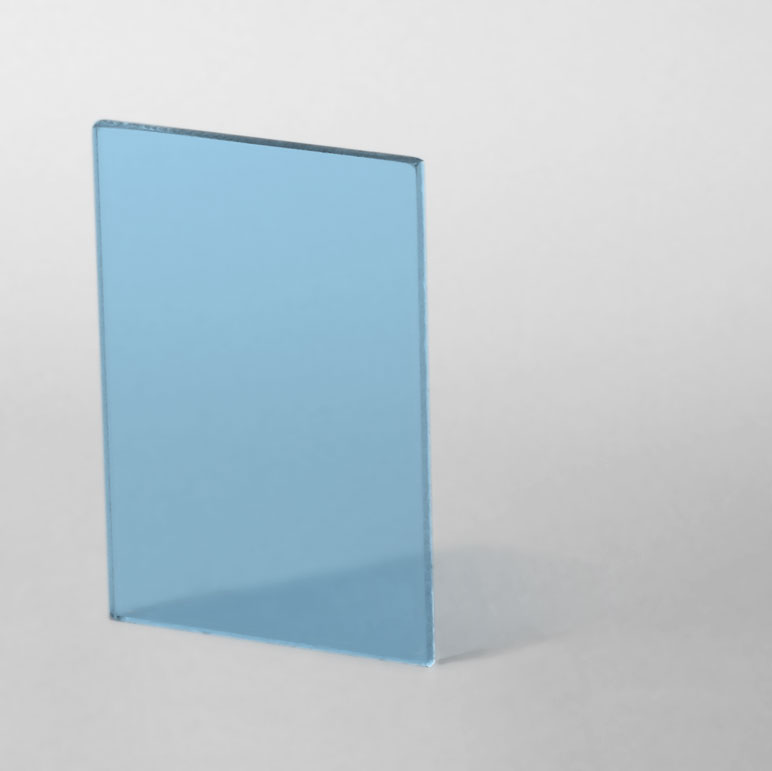

To attain more transparency, the low iron glass is used in which the iron content is extremely low. The low iron glass is characterized by their blue edges. To know more, check our post on low iron glass.

Iron content

The iron content in the glass types is of the order, Float glass > Clear glass > Low iron glass. In simple words, the lesser the iron content, greater the transparency.

Tinted glass

Tinted glasses primarily come in four colours namely, green, grey, blue and bronze. Each of them are created by adding certain metal oxides to the glass during production. Many other range of colors are also available depending on the requirements.

Tinted glasses are commercially used because of their ability to provide an additional aesthetic sense on top of the performance capabilities. They enhance the appearance of the building from the outside whereas improve the solar performance inside. So they are extensively used in building facades.

These glass types are the bottomline for many other composite glass types. Follow our blog to know about the advanced glass types in the market and more!!